-40%

DIY Pro Hot Wire Foam Cutter For Gun Case, Camera Case, Replacement Foam

$ 11.08

- Description

- Size Guide

Description

BUILD YOUR VERY OWN PROFESSIONAL QUALITY HOT WIRE FOAM CUTTING SYSTEMWatch it work above!

You are buying detailed

instructions only

for building a hot wire foam cutting system

No Parts, Materials or Supplies are included with this purchase

THIS IS AN INTERMEDIATE LEVEL WOODWORKING PROJECT

You

MUST

possess woodworking skills, as well as some basic low voltage electrical wiring skills in order to build this project

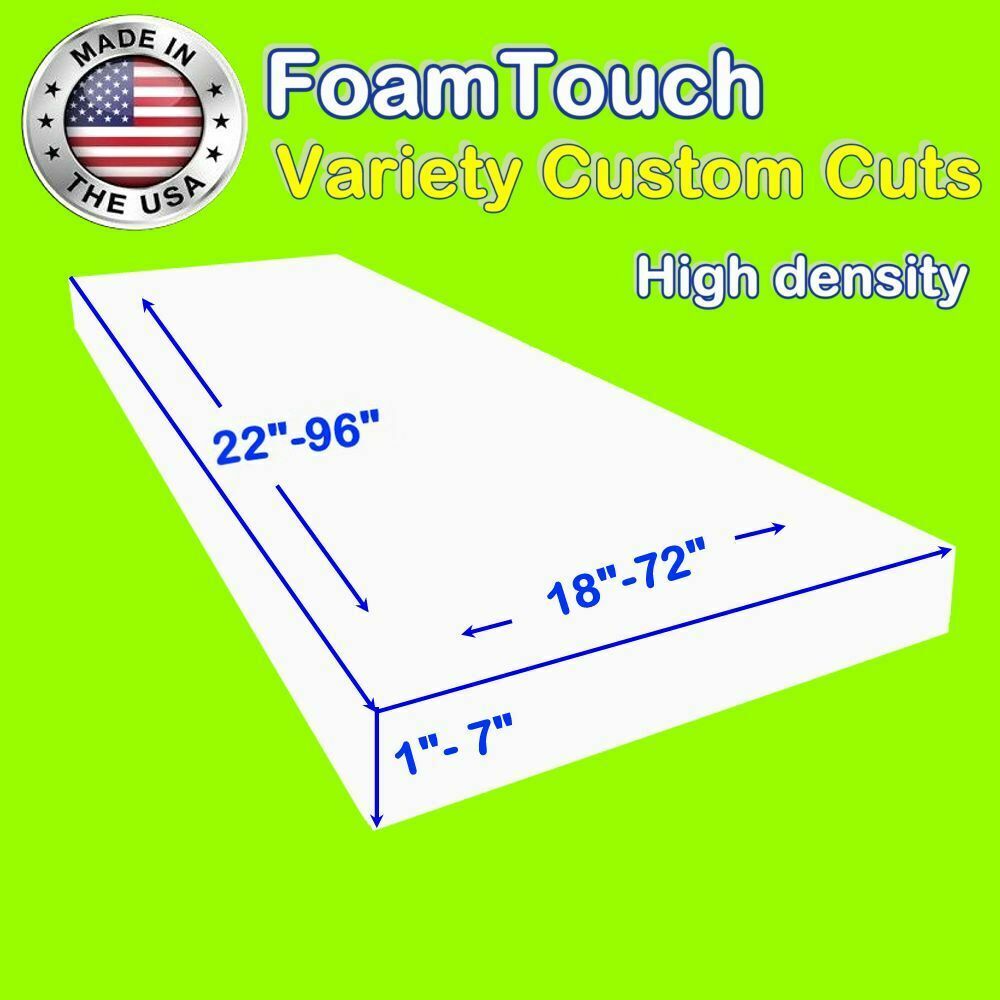

BUILT FROM A SINGLE 4 X 8 SHEET OF ½” THICK PLYWOOD

EXPECT TO SPEND ABOUT 0.00 US DOLLARS FOR THE PARTS, MATERIALS AND SUPPLIES REQUIRED TO BUILD THIS PROJECT AFTER PURCHASING THIS INSTRUCTION SET

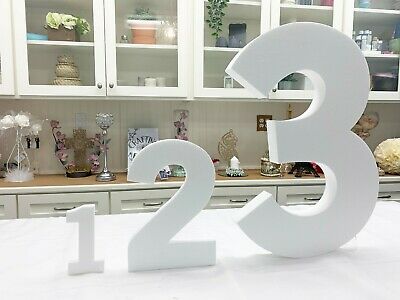

This system features a 24 inch by 48 inch foam cutting table which stands 35 inches tall and supports a hot wire foam cutting jig fashioned after a scroll saw with a unique wire tensioning system. The system has a cutting capacity of 9 inches in height, 36 inches in width and unlimited in length. With this system, you will be able to make accurate and incredibly intricate cuts in foam and Styrofoam for gun and camera cases, as well as, for other hobbies.

WHAT YOU GET WITH THIS PURCHASE :

You will receive a comprehensive set of illustrated

instructions only

for building a hot wire foam cutting system which includes:

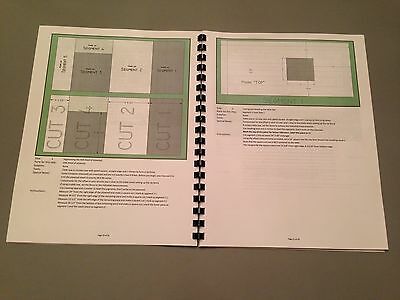

51 page, color illustrated, instruction set, printed double sided, on 8 ½ X 11 sheets of paper

Detailed step-by-step instructions for cutting, detailing and assembling the complete system

Detailed, dimensioned Illustrations showing exactly what you need to do

Shopping list of parts, materials and supplies you will need to purchase in order to complete this project

Shopping guide which tells you exactly what to buy and where to buy it

Cutting schedule for plywood parts needed to build this project

List of woodworking and other tools you will need to build this project

Basic instructions on how to cut foam like a professional with this system

You must own basic woodworking tools for measuring, cutting, drilling, detailing and fastening the required plywood components in order to build this project

If you are new to hot wire cutting, know that there are inherent risks in using these types of systems as the super-heated cutting wire will cause serious burns and injury if the hot wire is touched. Do not buy this instruction set and do not attempt to build this system if you are at all apprehensive about using hot wire cutting techniques or have reservations about your ability to build and use this system. PLEASE RESEARCH HOT WIRE CUTTING SYSTEMS AND TECHNIQUES and familiarize yourself with these systems and techniques BEFORE YOU MAKE THIS PURCHASE and attempt to build this system.

An intermediate level woodworker with appropriate tools should expect to complete this project in 8 to 12 hours.

If you buy this set of comprehensive instructions, and have the tools and qualifications mentioned above, YOU WILL, WITHOUT A DOUBT, BE ABLE TO BUILD A PROFESSIONAL HOT WIRE FOAM CUTTING SYSTEM. We have made sure nothing is left unanswered for you in the instructions!

The photos are of the actual pages from the set of instructions you will receive

THIS IS NOT AN INSTRUCTIONAL GUIDE ON WOODWORKING. WE DO NOT TEACH WOODWORKING IN THIS PACKAGE. WE TELL YOU HOW TO BUILD A WOODWORKING PROJECT RELYING ON YOUR WOODWORKING SKILLS. Please do not buy this package if you have no carpentry or woodworking skills or if you are not otherwise mechanically inclined.

ABSOLUTELY NO REFUNDS SHALL BE OFFERED ON THIS PURCHASE UNDER ANY CIRCUMSTANCES.

Read More:

The author is an Engineer and avid woodworker who, frustrated by the lack of reliable information about building Hot Wire foam cutting systems, decided to research and develop this system himself and write this 51 page step-by-step guide on how to build one. The design is supported by and modeled with a state-of-the-art 3D computer modeling software. The 3D illustrations in this guide make it very easy for you to visualize and understand the steps required to complete this project. If you too have been frustrated with trying to cut foam inserts for your gun or camera case and have had less than satisfactory results with “pick and pluck” foam inserts, you will appreciate the versatility and ease of use of this system and will be proud of the results you get. Don’t try the electric carving knife approach for cutting foam suggested on various YouTube videos as you will not get good results and may even injure yourself doing it. Considering the high cost of replacement foam inserts for your cases, this is a must have system to insure you get the best results from your investment in foam inserts. The foam cutting table you will build with this guide can also be used as a light duty workbench or a router table and can serve a multitude of purposes. If you have friends or family who need custom cut foam inserts for their gun or camera cases, consider setting up a small home-based business to accommodate their needs and make some money doing it. The system makes for a great hobby while earning you a little cash. Advertise your service in the local paper and develop even a wider market base for yourself. There are many hobbyists out there who could use the service you will be able to provide, cutting foam, using this system. For advanced woodworkers, we even offer suggestions on how to upgrade the foam cutting system by adding a tilting head cutting jig for making miter cuts. You will get a great deal of satisfaction using this system and will impress your friends and neighbors with something you built that produces fantastic results. We gave 4 sets of these instructions to 4 different individuals with varying skill levels in woodworking. All 4 completed the project and achieved a working system in less than 12 hours of work. You can do it too. Hope you have as much fun building and using this system as we did researching, designing and illustrating it for you. Have fun and work safe!